Bespoke Valve Packages. It’s What We’re Good at.

We specialise in industrial valve and actuator solutions that are built to suit your application.

We stock an extensive range of valves, from ¼” (8mm) to 24” (600mm) and associated electric and pneumatic actuators.

Our team has the knowledge and expertise to support you in the management and operation of your facility.

Talk to us to find out how we can help.

Industrial Valves and Actuators

We offer technical assistance in the selection and sizing of valves and actuators, with same-day emergency turnaround available.

Our products are assembled and tested by our knowledgeable team, supported by ISO quality accreditations.

Actuation accessories include custom-built control cabinets, solenoid valves, switch boxes, positioners, manual overrides, extensions and deadman’s handles.

Actuator Manufacturers

ESSCO are the main UK agent for NUTORK Electric & Pneumatic Actuators.

We also have many years experience with actuator manufacturers including: Electric: Valpes, Enolgas, Bernard, Rotork, Auma, HQ, Pneumatic: Kinetrol, Norbro, Hytork, Air Torque

Marine Applications

With marine valves in a range of materials including all grades of bronze, iron, steel, monel, stainless and super duplex, we offer a solution for most applications.

We’re the experts when it comes to the identification and specification of valves and valve related products.

Where possible we can attend your site or port to help identify the best solution.

Our Service

Impartial advice and solutions

We are a proudly independent company offering impartial advice and solutions to assist in all aspects of valve selection.

On-time quotations

Our service standards recognise the need to provide quotations, products and projects on time and to a deadline.

Solid relationship and distribution agreements

Our distribution agreements with some of the key European valve & actuator manufacturers mean we can offer solutions from stock for all industries, including: –

- Oil & Gas

- Petrochemical

- Pharmaceutical

- Consumer Health

- Brewing

- Defence

- Water & Wastewater

Documents

Latest News & Case Studies

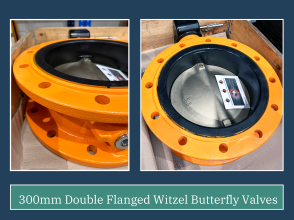

Bespoke Marine Valves

Our EPV team recently sourced and supplied these bespoke valve packages for the marine industry. They will be used on a Ro-Ro (roll on–roll off) ferry, which is being refurbished in a dry dock refit. All come with DNV certification for peace of mind. Valves supplied include:300mm Double Flanged Witzel Butterfly Valves2 ½” Straight Pattern…

Danfoss Pressure Independent Control Valves in Stock

We stock a range of Danfoss products in our Little Book of Valves. This includes the popular Pressure Independent Control Valves shown below. Our Series EV1352 and EV1354 are perfect for your plant room or heat network projects. You can find product information in the Little Book of Valves. These are in stock and ready for…

Introducing the Little Book of Valves

Sometimes the best things come in small packages. This is true of the Little Book of Valves, our new range of bread-and-butter building services products.

Bespoke Valves for Superyacht

EPV recently supplied these bespoke packages for a wet exhaust gas system on a 105m superyacht.